What are wet scrubbers?

Wet scrubbers are devices which remove particles and gases from exhaust streams. We call them “wet scrubbers” as they capture the unwanted particles (gas) through a liquid.

Wet Scrubber Solutions

At Parsons, we supply multiple wet scrubber solutions for a variety of applications. We are well aware that different wet scrubbing application will contain different variables. Additionally, these variables will also affect the size and type of scrubber necessary.

Our engineers investigate the site and, after analysis, suggest and implement a solution. We can install our wet scrubbers individually, or as part of an odour abatement package. Our scrubber designer can help you to determine critical values, such as how fast the air goes and how wet the packings are.

When fume or odour molecules disperse into a gas stream, treatment of the gas stream becomes more challenging. The simple answer is to concentrate. This is a bit tricky with gasses, so the answer comes with capturing them in a liquid solution. Once in solution, there is time for neutralisation to occur, but the capturing is the hard part.

Wet scrubbing is a convenient way to rid factories and manufacturing environments of bad odour and pollution.

Other companies offer temporary services which simply “mask” the smell, similar to using an aerosol. Parsons, however, eliminates the odour by removing the problematic particles themselves.

How does wet scrubbing work?

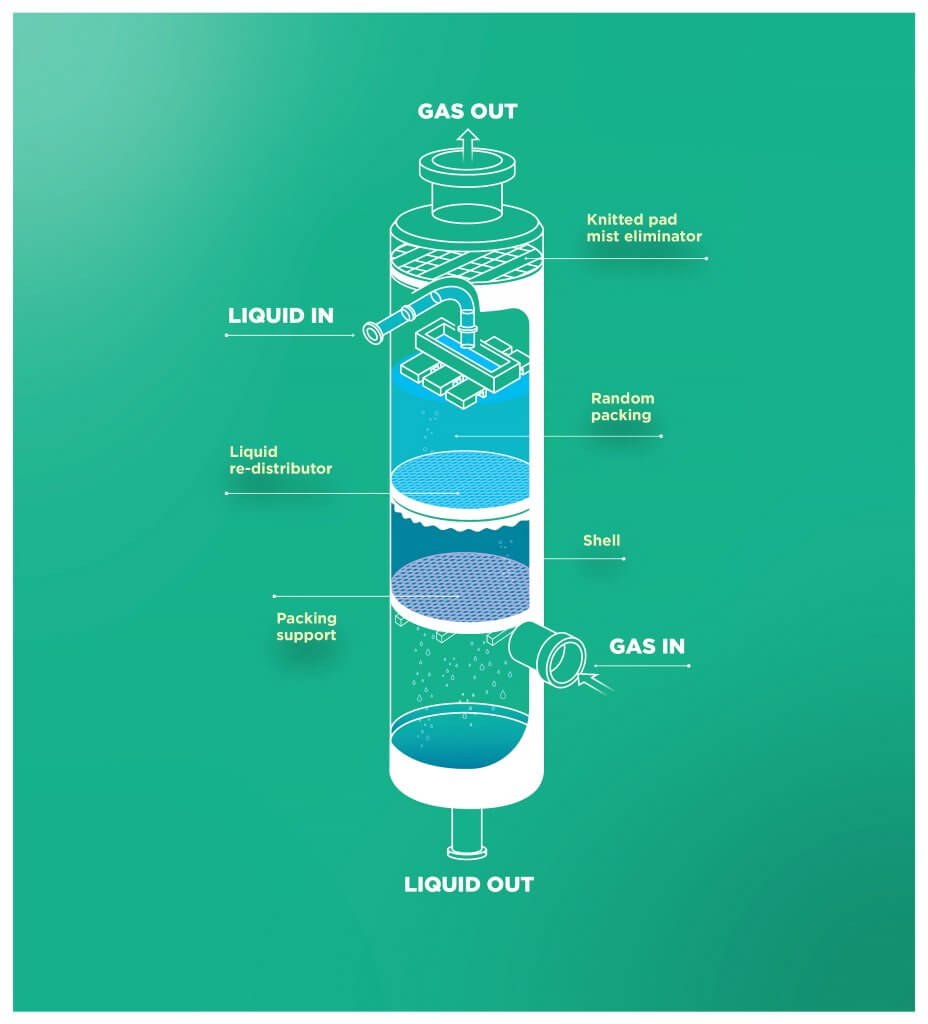

The gases then pass up through a bed of random packings, braced on a packing support grid, where they come into contact with the liquid stream flowing in the opposite direction down through the bed.

As the gas and liquid flow past each other, the soluble gases absorb into the non-volatile liquid stream. The cleaned gas then passes out through the top of the column via a demister pad to remove any loose droplets.

The liquid is recirculated from the sump at the base of the column to the top of the packed bed, where specially designed liquid distributors ensure the bed is thoroughly and evenly wetted to provide efficient mixing of the gas and liquid streams.

The equilibrium between the gas and liquid phase for any wet scrubbing process is vital to ensure the maximum removal of the contaminants or odours. Moreover, when we use a recirculating solution for the removal process, it is essential to ensure that the liquid composition enters the scrubber column at the lowest possible level.

Furthermore, this is even more important in odour scrubbing applications where we measure emission levels on the ‘Parts per Billion’ scale, rather than the ‘Parts per Million’ scale, which is generally associated with gas scrubbing such as acid fume removal.

Odour abatement and chemical scrubbing solutions

If you’d like to know more about our wet scrubber services, read the odour control solution we provided for a wastewater sludge treatment facility here.

Additionally, we have a case study that highlights the wet scrubber solutions we found for a poultry processing plant, here.

If you’re looking for a quotation, or for further information on our services in general, please fill in our contact form. Or call us on 01922 404 318

More information on Wet Scrubbers.

Unfortunately, due to the multitude of factors to be considered in designing an odour control plant, we are unable to offer a ‘Click Here, pay online, deliver tomorrow’ service.

Our plants designed and built to order allowing maximum compatibility with the customers needs, this obviously incurs a not insignificant lead time. If time is critical we may well have a suitable option for near immediate installation available through our Plant Rental department.

Please give our sales department a call, who should be able to help with your queries from “Is it possible?”, through rough ballpark figures to complete system quotes.